Raimondi Cranes SpA, established in 1863, has announced a transformative approach to heavy lifting technology, the luffing jib LR330. Showcased to Raimondi’s exclusive agent network ahead of wider release, the LR330 luffing jib crane will officially begin shipping in March to fulfill agent presell orders, and is now available for wider purchasing.

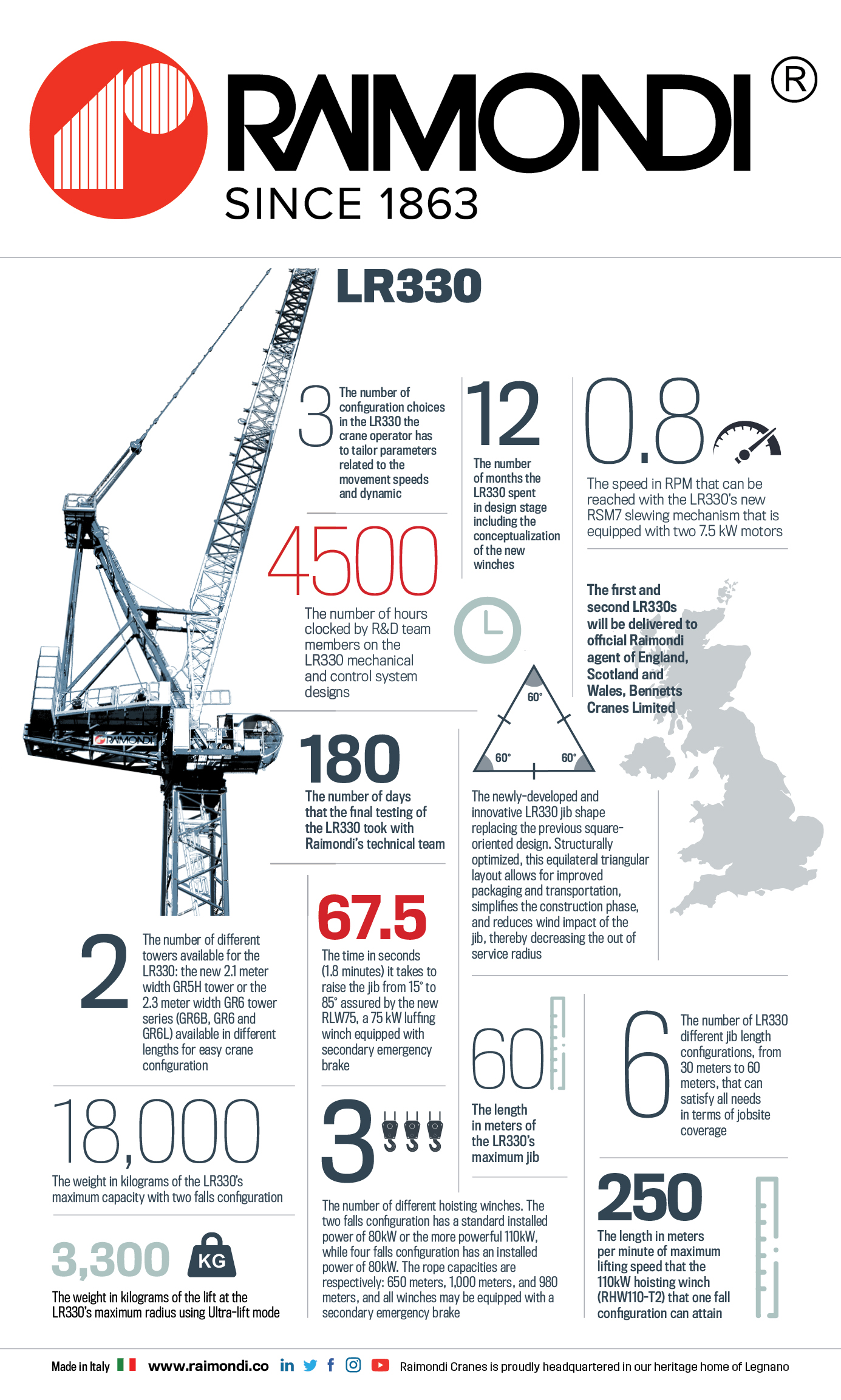

“Raimondi has realized our value proposition through research, trials and finally, development. We’re proud to present a technologically advanced, superior performance luffing crane, fully European in manufacture, to the market,” said Eng. Domenico Ciano, Technical Director, Raimondi Cranes. “The LR330 is productive, durable, strong and efficient. As the flagship crane of the new luffing range, we have incorporated a breakthrough equilateral triangular jib design to enhance several different aspects of the machine. Structurally optimized, this innovative layout allows for improved packaging and transportation, simplifies the construction phase, and reduces wind impact on the jib, thereby decreasing the out of service radius,” explained Ciano.

The LR330’s ease of use is most apparent to crane operators who can now control and tailor the machine’s work to their preferences, thereby reducing jobsite stressors. Together with the new Raimondi safety control system, there is a significant advancement in performance and control of the LR330’s three movements. “Crane operators can now choose between three different configurations, enabling a change in parameters related to the movement speeds and dynamic. This functionality allows the operators to align the crane closer to their specific needs. Further, to reduce pressure on the operator and simultaneously increase the overall level of onsite safety, the safety control system’s installed sensors monitor all of the crane’s movements and monitor the load, supporting the operator as site hazards approach. Alerting the operator with alarms and direct intervention, the LR330 is both agile and intelligent,” said Ciano, describing a few of the LR330’s operator-centric characteristics. Ciano added that working at height has also been factored in with the crane’s simplified installation and dismantling procedures.

The Raimondi LR330 is the newest luffing jib crane in the range with a maximum jib length of 60 meters and a maximum capacity of 18,000 kg, with two falls and four falls configurations. At the maximum radius, it can lift 3,300 kg in Ultra-lift mode. Six different jib length configurations, from 30 meters to 60 meters, satisfy all needs in terms of specific jobsite configurations. The LR330 may be equipped with three different hoisting winches: standard installed power of 80kW or the two falls configuration with the more powerful 110kW, while the four falls configuration has an installed power of 80kW. The rope capacities are respectively: 650 meters, 1,000 meters, and 980 meters, and all winches may be equipped with a secondary emergency brake.

Raimondi’s newest luffing crane follows the October 2017 launch of the MRT234 flattop tower crane, boasting the optimal match of mechanical, structural and electronic control design, allowing for increased productivity, safety, and better user-interface.

Related: Raimondi launches the MRT234 flattop tower crane, the latest in heavy lifting innovation